Pressure Safety Valve (PSV)

A pressure safety valve (PSV) is a valve used to protect pressure piping and pressure vessels from over pressuring. These valves are commonly used in the oil & gas industry and are required for safe design practices. PSV's are used in gas, liquid, and steam services. PSV's are sized for both normal flow conditions as well as the possibility of fire.

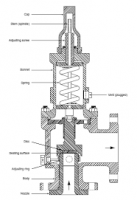

A pressure safety valve automatically actuates when the pressure on the inlet side of the valve reaches a set pressure point. Once the pressure is reached, the built up pressure pushes open the valve disc and releases the pressure. Once the pressure decreases below the set point, the valve disc closes.

PSV's are typically vented to atmosphere, flare systems or vent stack systems. Regulations determine the limitations on flaring and venting. In some cases where pressure is created from a pumping systems, incompressible liquids may be tied back into tanks or the pump suction depending on the flow conditions, temperature, and pressure.

There are three (3) common types of pressure safety valves:

- Conventional

- Balanced Bellows

- Pilot Operated

Conventional Pressure Safety Valves

A conventional PSV uses a spring to set the pressure at which the PSV's relieves at. When the pressure builds up to the set point, the spring will then compress and allow the gas or fluid to pass. As the pressure decreases below the set point, the pressure expands stopping the flow from relieving.

Conventional PSV's are the most come PSV's used and can be used in a large variety of applications. They must be properly maintained and operated to maintain reliability. However, the relieving pressure affect the efficiently and usability of this type of valve. The PSV may also chatter if too much back pressure is built up or if the pressure is set too close to the normal operating pressure.

Balanced Bellows Pressure Safety Valves

A balanced bellow PSV consist of spring-loaded valve similar to a conventional PSV. However, a balanced bellow PSV contains a bellows arrangement to keep back-pressure from affecting the set point. Balance bellow PSV's are commonly used when the back pressure on the valve exceeds 10%.

Pilot Operated Pressure Safety Valves

A pilot operated PSV uses the inlet / upstream pressure to push down on a piston in the valve to keep the valve closed. Pilot operated valves can be set much closer to the operating pressure than other PSV types. Pilot operated valves are also not affected by back pressure. Pilot operated valves due require more maintenance and are more expensive than other types of PSV's.

Pilot operated PSV's can be snap acting or modulating. For snap acting PSV's the piston in the valve snaps fully open when the set pressure is reached and snap closed once the pressure is relieved.

Modulating pilot operated valves open gradually to slowly relieve pressure. The more the inlet pressure raises above the set point the more the piston opens to relieve the flow. The system is controlled by slowly venting off the pressure on the piston as required to control the pressure relief.

Associated Categories |

| Valves - Safety and Relief |

Comments regarding